Helio Additive to launch new slicing software that ‘increases 3D printing output and reliability’

Chinese application commence-up Helio Additive has unveiled plans to start a new method which is created to assist makers everywhere ramp up their component throughput and regularity.

Helio Additive’s program revolves all-around a physics-based AI engine, which adapts the way pieces vulnerable to warping are sliced, so that they’re fewer probable to develop the form of nonconformities in the course of printing that make them unfit for function.

In carrying out so, the firm states that its know-how allows consumers to greater stay clear of print failures, reach an up to 10 situations bigger charge-for each-portion ratio, and in the long run to “supercharge” their complete 3D printing workflow.

“In the last five a long time, components in 3D printing has outpaced the development of software package capabilities, leaving a bottleneck for firms completely ready to adopt additive [manufacturing] in their workflow,” explained Helio Additive CEO David Hartmann. “At Helio, our purpose is to diminish the void between application and components and in the end enhance the output and reliability of 3D printed elements in creation.”

Helio Additive’s novel AI engine

According to Helio Additive, an common of a single in six 3D prints fails and the technology has a ‘scrap rate’ of more than 80{5376dfc28cf0a7990a1dde1ec4d231557d3d9e6448247a9e5e61bb9e48b1de73}, so it has charges that are “far way too high” as opposed to those people of mainstream manufacturing. What is additional, additive manufacturing adopters intending to use the engineering for serial generation applications generally require good quality guarantees, something the organization states are at this time lacking in the sector.

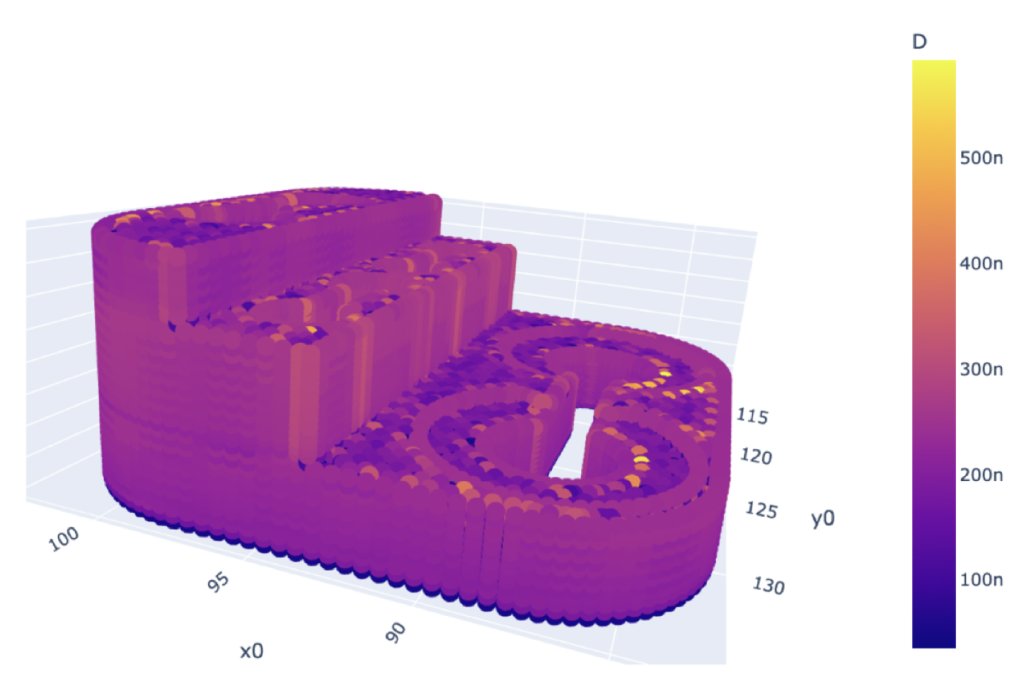

In an work to aid these manufacturers accomplish better certainty, the business has therefore developed a new AI engine, able of breaking down 3D versions into single voxels. As soon as it has accomplished so, the application charts the stress peace and thermal historical past of each and every of these voxels, right before applying the resulting facts to adapt the way areas are sliced, so that they steer clear of failures caused by heat variations during printing.

“The new technology of printers and products have extremely strong performance envelopes, but are printing at roughly one fifth of their greatest pace,” explains Helio Additive. “At the same time, engineers battle with repeatability and prints are unsuccessful up to five occasions, in advance of getting a print suitable. Helio’s physics-primarily based program utilizes device studying and physics simulation to enhance repeatability of printed pieces by linking the printing procedure with necessary outcomes.”

While Helio Additive acknowledges that the way a system’s scorching-end impacts prints as it passes more than them can be various, with polymers like PLA not struggling so substantially from temperature improve, it highlights how the bigger thermal coefficient of components like Computer and PA often results in them to come upon high-quality difficulties when subjected to shorter bursts of warmth.

Employing its system, the firm thinks that end users not only stand to enhance the layer adhesion and geometric compliance of these pieces, but deliver their devices with a method-optimizing ‘brain.’ In truth, though the business stays in the early levels of rolling the application out, it anticipates that in potential, this ‘brain’ could even be employed to help much more new adopters enter serial creation.

Expanding into the 3D printing industry

Considering the fact that it was proven in the town of Changshu in 2020, Helio Additive has established out on a journey to build out its main technological innovation and deploy it within just producing settings. In that time, the business has assembled a crew with a robust mixture of tutorial and sector skills, including ex-Covestro person David Hartmann, and its CTOs Zhenqing Li and Priyesh Patel, who hail from Ohio State and UCL respectively.

At present a crew of just ten, Helio Additive is now commencing to scale its business and technologies groups, and is reported to be actively recruiting engineers, information researchers and programmers in both Changshu and Shanghai to help its ongoing growth.

Another way the firm is in search of to obtain traction in the 3D printing sector is by means of market partnerships, and it not long ago introduced these a collaboration with Amesos as perfectly as 1 of its investors, Polymaker. Performing alongside the two businesses, Helio Additive is established to assist them hone a new substantial-velocity 3D printing solution they announced previously this calendar year.

Based about Amesos’ Blade 1 process and a custom Polymaker materials, the companies say that their ‘FFF 2.0’ methodology will deal with a number of the drawbacks involved with typical FFF 3D printing, notably individuals encompassing throughput.

Aside from the R&D get the job done it is conducting as section of the job, Helio Additive is also doing the job on a standalone variation of its software, which it intends to deliver to current market. As of nevertheless, there’s no verified date for the platform’s alpha release, but it is anticipated to be launched at some issue later this yr, and the firm’s actively looking for companions to exam its capabilities.

Individuals fascinated in finding out extra about Helio Additive’s physics-centered AI motor can do so by means of its web-site.

To remain up to date with the most current 3D printing news, never neglect to subscribe to the 3D Printing Business publication or follow us on Twitter or liking our website page on Facebook.

For a further dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and pictures of 3D printing in-motion.

Are you searching for a position in the additive production business? Visit 3D Printing Jobs for a range of roles in the business.

Featured image demonstrates the household web site of Helio Additive’s software package. Graphic by means of Helio Additive.